| Vol. 1 No. 10 | page 2 | March 14, 1952 |

| Vol. 1 No. 26 | pages 1 & 6 | July 4, 1952 |

Many persons think that the Chemical munitions which have been manufactured and are stored at this depot are of no necessity. After all, it is said, that the recent war was fought without the use of gas and that other weapons that have recently been developed has put gas warfare back into the small-time categories. Certain rapid strides were made in offensive use of Chemical Warfare as a result of the recent war, resulting in agents far more toxic and methods of dispersion far more efficient than anything hitherto known.

We live in a age when full preparedness is essential and it is inconceivable that any nation which might attack us would disdain the use of toxic agents of all types. Therefore, the Chemical munitions which we have stored at this depot can be considered an insurance whether or not they are used. Deployment of gas would, in all probability, be by air and to a lesser degree, by artillery, therefore, "Chemical Warfare is Air Warfare".

The Chemical Branch is responsible for and furnishes technical supervision for all chemical activities on the depot. These normally consist of preservation, normal, maintenance, surveillance and storage of chemical corps munitions; decontamination of any and all items contaminated with chemical agents, removal of leaking chemical corps munitions to the burning ground, demolition or demilitarization of hazardous chemical corps munition.

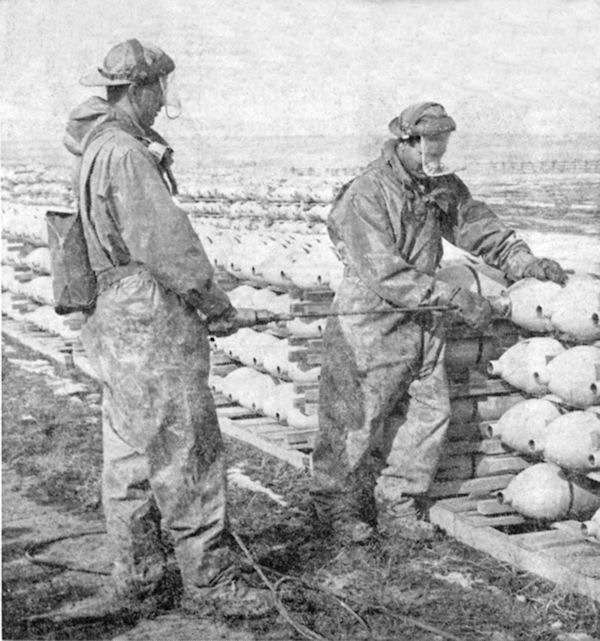

The present operation being performed by the Branch on M-70, H-filled bombs consists of fabrication of lead washer on nose plug by utiliaztion present closure plug, chambering of forward inside edge of burster well tube to insure that the lead washer on the closure plug is seated properly and forms a tight fit, and the installation of lead gasketed closure plug. The purpose of the operation is to prevent contamination from further leakage and to permit the retention of burster well leakers from reworking with new burster wells. The nose plugs are initially removed by personnel clothed in impermeable suits consisting of rubberized material.

During hot weather it requires personnel to take frequent breaks in order to cool off. The nose plugs are then decontaminated and transferred to a degreaser located in building 1813. After completely degreased the plugs are sent to the machine shop where personnel of the branch, as well as military, fabricate the lead washer on plugs. Wider aisle space was required in the storage pad, therefore bombs are being moved to allow equipment used the operation of chamfering forward inside edge of burster well tube to operate between the aisles. The chamfering equipment consists of a slow speed electric motor mounted on a two wheel hand cart. Attached to the motor is a flexible shaft to which is attached a fluted reamer. Threaded guides are inserted into the forward end of burster well tube by means of electric nut runners. The spindle of the fluted reamer is inserted into a hole in the guide reaming out a 45 degree chamfer. Electric nut runners remove the guide, then the lead gasketed nose plug is inserted and tightened to the proper degree to form a tight fit. Personnel who are performing the chamfering operation and insertion of plug are divided into small groups with an experienced and higher grade ammunition renovator in charge of each group. These groups are responsible for care of each of their equipment. One man is assigned the duties of over all repair and maintenance of equipment. This is performed in a portable shack located at the operation and is easily moved as the operation procedes in the area.

Personnel are equipped with the latest type of gas mask which will assure them sufficient protection under normal concentration of gas. They are required to carry their mask slung to the body at all times. A daily check and examination is required by the individual to insure its proper function. The supervisor performs a weekly inspection and drill. Periodic gas chamber exercises are held where personnel wear the mask in a high concentration of tear gas. The object being to test the fit and efficiency of the mask and to instill confidence in the mask. When working on leaking or hazardous bombs, personnel are required to wear necessary protective clothing.

Other work performed by the branch consists of pressure tests and agent quality tests of certain other chemical munition for the purpose of detecting a dangerous or unserviceable condition.

In the event of a leaker in bombs stored in igloos, resulting in a high concentration of gas in the igloo, the branch has a portable exhaust fan. The ventilator on the top of the igloo is removed and the fan installed readily to permit removal of gas concentration in the igloo. Personnel required to enter the igloo to shut off or control the leakage on the bomb, are equpped with the latest type of oxygen breathing apparatus to insure complete protection.

A large amount of tools used have been designed by personnel of the branch. Several men have received monetary awards through the suggestion award program which is greatly encouraged. A tool was designed for removal of needle valves on bombs which has been instrumental in saving several thousands of bombs which had hitherto been destroyed. This tool is now being employed by other depots.

Originally the only building in the branch consisted of a 10 X 10 shack, known as the "Warm UP Shack". This was used as a field office for the foreman and to store tools and as a lunch room. Later in 1949, Dunnage house No. seven was obtained. This building is equipped for performing agent quality tests on bombs and was also used as a change building. In August of 1950, due to additional requirements of personnel, a larger change building was required. A building 20 x 60 was moved out into the area. Personnel have gradually performed improvements on the building such as painting the interior and covering the outside with red roofing.

A tool room has been built in the building and the old warm-up shack was moved alongside for storing equipment. Recently lights have been installed in the building and also a water cooler. The source of power is a Schramm generator. There is no water available in the area but in the summer months water for washing is stored in a 1000 gallon tank.

Another piece of equipment recently installed is a power-driven apparatus for decontamination. This apparatus consists of a 400 gallon water tank and is used for hauling water for washing, decontamination of the area and vehicles and can be used for fire fighting. Showers are equipped on the apparatus in the event a person becomes contaminated, he may be readily decontaminated. The machine is also equipped with a portable heater capable of heating the 400 gallon in 10 minutes.

The branch is responsible for obtaining its own supplies and equipment. One man is assigned the job as tool-keeper and performs various other duties, such as obtaining supplies, cleaning and decontamination of protective equipment and cleaning up the change building.

Training courses in chemical safety measures are given to the individual at periodic intervals in order to carry out his job with least risk from chemical agents. Every individual whose job brings him in contact with chemical ammunition must be familiear with the indications that warn of presence of chemical agents, realize the potentialities and effects of the agent. He must know how to use his protective equipment to avoid or lessen injury, know how to keep his protective equipment in good condition and know what to do for injuries from chemical agents. Immediate first-aid is the responsibility of the individual and must be given promptly. He must be able to decontaminate himself, other workers and tools and equipment.

To become familiar with all phases of this operation is only developed through several months of experience.

Being a small branch, the Chemical Branch must be also very flexible and the personnel are required to perform other duties, such as operation of pneumatic and electric forklifts, truck driving, operation of schramms, air compressor and performing duties of checkers.

There are presently 37 men and women assigned to the branch. Seven additional men are loaned from Storage Division and one officer and 12 enlisted men from Technical Escort Detachment Army Chemical Center, Maryland, are working on the present project.

| Vol. 1 No. 27 | page 4 | July 11, 1952 |

The Chemical Warfare Service formed the Technical Escort Detachment as a unit in September 1943 at Camp Sibert, Alabama. The unit at that time was known as the Guard and Security Detachment.

The unit was formed for the purpose of escorting and safe-guarding hazardous chemical shipments by rail, water, air and motor vehicle throughout the zone of interior and to overseas theatres of operations. Upon activation the detachment had a complement of 35 officers and 100 enlisted men commanded by Col. Garland M. White, the present commanding officer. Soon thereafter, the unit was ordered to Edgewood Arsenal, Maryland, and the detachments officer and enlisted strength was expanded to 50 officers and 300 enlisted men in order to meet the shipping requirements brought about by World War II production activities.

During the late war, the organization participated in over 1500 individual escort assignments without serious mishap or accident: an enviable safety record. For this remarkable achievement, the unit was awarded the Unit Meritorious Award, in April, 1946.

After World War II, the Chief of the Chemical Corps, ordered the Technical Escort Detachment to be retained at reduced strength to perform the following missions: escort of chemical, biological, and radioactive materials, demilitarzation and decontamination of Chemical Corps munitions, certain plant security assignments and general safety work within the corps.

The unit was reduced to five officers and 35 enlisted men in April, 1946 due to the effects of demobilization. The organization operated on a limited scale until the outbreak of hostilities in Korea in 1950.

Concomitantly with the acceleration of mobilization, the organizations strength was again increased to 10 officers and 65 enlisted men; which is the units present operating strength.

During the past two years the detachment has acquired additional responsibilities, such as the renovation or destruction of chemically filled munitions. The unit has been called upon from time to time by the other Technical Services to furnish destruction or renovation teams to destroy or renovate, deteriorated or obsolete chemical munitions which are considered hazardous to life or property. Now, since the detachments work has centered primarily in the munition field, the Chemical Corps is considering redesignating the unit as a munitions Safety Control Team.

The majority of the detachments personnel presently here on temporary duty at the depot, are in the majority all recent graduates of the following Army or Navy service school: The Explosive Ordnance Disposal Supervisor's Course at Indianhead, Maryland, The Explosive Ordnance Disposal Specialist Course at Aberdeen Proving Ground, Maryland and the Ammunition Renovator Course at the latter installation.

During the past 24 months the detachment has participated in renovation and destruction missions at the following installations: Redstone Arsenal, Alabama, Tooele Ordnance Depot, Utah, Dugway Proving Ground, Utah Rocky Mountain Arsenal, Colorado and Pine Bluff Arsenal, Arkansas.

The future for the detachment is bright with a full schedule of interesting assignments to be completed during the coming fiscal year.

| Vol. 2 No. 21 | page 1 | May 22, 1953 |

Major Stephen M. Wondrasek has been sporting his new gold leaves less than two weeks but, to celebrate his promotion, he tossed the traditional promotion party for his brother officers and their wives last Wednesday at his quarters.

Major Wondrasek has 17 years in the army. He enlisted in 1933 and, with the exception of three years, from 1938 to 1941 when he was a member of the R. A. Reserve (inactive), he has been on active duty since his enlistment.

An officer for the past ten years, the new major has been in the Chemical Corps during this decade and has been Chemical Officer at the Depot since July, 1950.

| Vol. 5 No. 8 | page 1 | Feb. 21, 1957 |

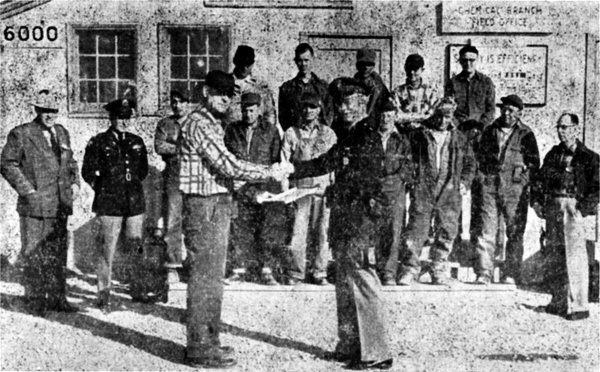

Major John Blette, Black Hills Ordnance Depot at Igloo, presented a special Certificate of Commendation for safety achievement to Clair E. Alspach, foreman of the Chemical Section at BHOD, at a ceremony held at Depot Headquarters at Igloo on February 13, 1957. Mr. Alspach accepted the award on behalf of the civilian personnel assigned to the chemical operations at the depot. In presenting the certificate, Major Blette noted that the Chemical Section had completed a five year period of continuous operations without a lost time accident. The Labor Department's Statistics Bureau shows that the accident frequency rate of 4.04 per million man-hours worked by civilian personnel in Chemical Corps operations compares very favorably with 12.10 per million man-hours average of "all manufacturing."

The work performed by the chemical handlers at BHOD requires close contact with (1) mustard gas, which causes slow-healing burns and inflammation of the nose, throat, trachea, bronchi and lung tissue; (2) phosgene gas, which affects the lungs and damages capillaries, causing seepage of watery fluid into the air cells of the lungs causing them to become so flooded that air is excluded and the victim dies of oxygen deficiency and (3) cyanogen chloride gas, which interferes with utilization of oxygen by body tissues and hemoglobin and also poison the central nervous system.

The safety program at BHOD requires that proper masks, permeable and impermeable clothing be worn by men working with toxic agents. Also full use of the Army's latest chemical detector kits and decontamination techniques and procedures are utilized in dealing with leaking or spilled toxic agents.