Renovation - Special maintenance operations required to renew serviceability, and

involving replacement of a component or group of components in ammunition and, in some cases,

ammunition components.

(From TM 9-1904, Ammunition Inspection Guide, 2 March 1944)

| Vol. 1 No. 10 | page 1 | March 14, 1952 |

Editor's note: This is the first of a series of articles designed to let the employees of the depot know what the other Divisions do.

By Jack Lee

Long after most of the depot has closed up shop for the day, a long look southward into the restricted area will show lights still ablaze - the Renovation & Demilitarization Branch is getting in some of its best licks in producing effective ammunition for our fighting forces.

This, the largest branch on the depot, employs well over 300 people in the accomplishment of one of the depot's most important missions - the restoration and modification of ammunition to a completely servicable condition. In order to give some idea of the size of the operations it might be interesting to note that over $500,00 worth of buildings and equipment is used by the branch.

A typical job performed by the Branch is the renovation of a type of rifle grenade usually employed in combat against tanks. This type of ammunition has proved very effective in the field and is in great demand by our combat troops. Work on this item was begun upon direction of higher headquarters who also furnished a typical procedure for the operation. This typical procedure is studied and reviewed by depot personnel and adapted to the depot's working technique. Necessary approval is obtained, supplies, equipment and components are requisitioned, personnel is assigned and the job is ready to roll.

Each individual has a specifically assigned task in the production line. Working behind steel barracades and protective shields, employees disassemble, remove old components, insert new components and reassemble each item of ammunition. Each round of ammunition is cleaned and painted and emerges from the line as a brand new item. It is then repacked and placed in storage. Not all employees, however, are actually engaged in work on the ammunition itself - the task of supply, transportation, heating and trouble shooting is a huge job in itself.

Morale is high in the Renovation & Demil Branch, and a friendly spirit of competition exists between shifts in getting out maximum production. A chat with any operator on the line, however, reveals that high production is not the main goal, but quality of the finished product and safety in operation are the working criteria. Safety is the thought uppermost in all employees' minds and the Renovation & Demil Branch is a vivid example of the expression "a safe operation is an efficient one."

| Vol. 2 No. 26 | page 1 | June 26, 1953 |

Captain Alphonsus E. Costello has been transferred to the Depot as Renovation and Demilitarization Officer, following a three year tour of duty in the European Command. A native of Passaic, New Jersey, Capt. Costello attended the Oakland Military Academy at Oakland, New Jersey, and has been in the service since 1941. Capt. and Mrs. Costello have two children, Michael, age six, and Karen, three and one-half.

| Vol. x No. xx | page x | July, 1954 |

The Walrus; July, 1954; BHOD-TV, demil of 250 and 500 lb bombs; Major John Blette, Assistant for Supply Operations;

Gerner Olson, Deputy Assistant for Supply Operation; Randolph Orbaugh, Branch Chief; Walter Flammond, Assistant Branch Chief.

"This operation, for the Air Corps, covers complete demilitarization, cleansing, painting and stencilling, and when

the good-as-new cases are ready to leave R & D, they are shipped to other installations for reloading with the latest type of explosive filler."

| Vol. 5 No. 27 | page 1 | July 4, 1957 |

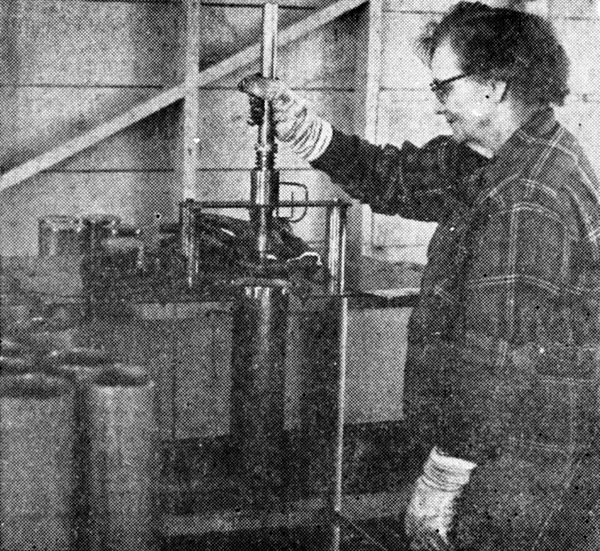

DISTAFF MEMBERS of the Storage Division team include Mrs. Wilma Anderson who works as

an ammunition renovator in the Maintenance Branch. She is show stenciling identifying data on the

base of a 105mm cartridge case. Mrs. Anderson is one of the two women still employed as a renovator.

She first began work for the Storage Division in 1951 in the General Supply Area and was promoted to

renovator work a year later.

| Vol. 5 No. 27 | page 2 | July 4, 1957 |

KEEPING TAB on the component parts of the 105mm gas shell and cartridge case calls

for frequent and accurate checks along the production line. Here, Mrs. Esther Murray makes a

count of the cartridge cases as they move along the line. Each item which enters the production

line must be accounted for, this includes component parts removed for distruction or salvage as well

as new components added. Mrs. Murray has been a spot checker since 1952.